The manufacturing process of nicotine patches 21 mg

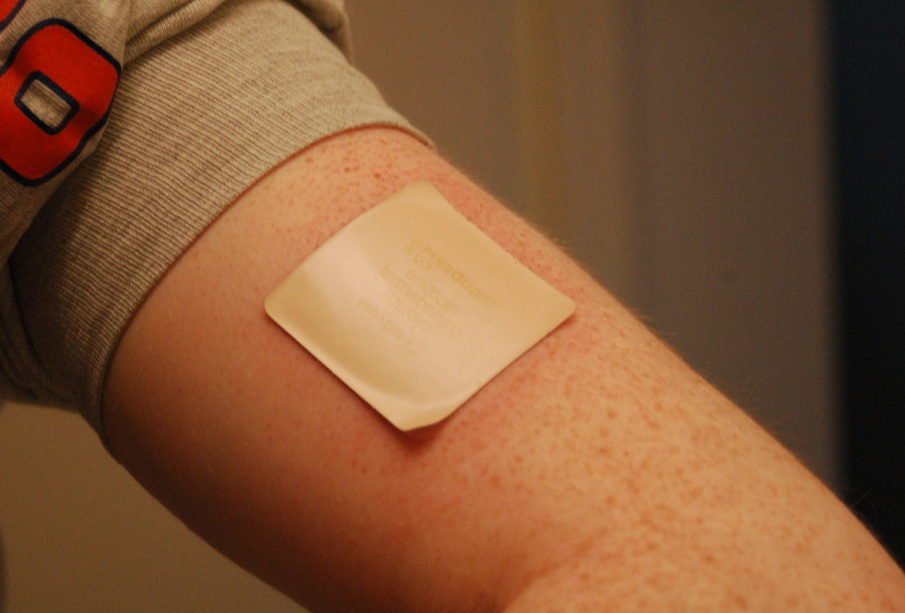

A nicotine patch is a device processing to deliver nicotine through the bloodstreams and into the skin. Patches are used to prevent the smoking experience by using nicotine products. This type of drug delivery process is called as Transepidemal patches. A nicotine patches 21 mg is preferred for heavy smokers. It consists of drug cenote and sandwiched between the catches the back layer and the forward part are the adhesive layers that fix to the skin.

The drug slowly enters into the reservoirs and travels through the skin and into the bloodstreams. Through skin certain chemicals enter into the body and nicotine drugs have a proper chemical characteristic.

Raw materials of nicotine patches

In cigarettes, nicotine is the major chemical component. The body itself develops a psychological as well as physically longing for the nicotine. The patches help to satisfy the craving, while the smokers can quit smoking. In some cases, cigarette causes people to suffer from overdosage of nicotine. According to the type of patches, the amount of nicotine compound quantities varies from 5% to 50%. The pure form of drugs is used in the nicotine patches. The consumption of nicotine patches varies, the patches with 7mg are prepared for heavy cravers while 4 mg is manufactured for medium cigarette users and finally the 1mg for the low smoker.

Manufacturing the carrier preparation

The manufacturing of nicotine patches is constructed based on their type. In general, patches are made by serval techniques, which are prepared to create a uniform diffusion of pores. The main aim of the process is to create a thin membrane with a multitude of microscopic channels where the drug can get diffuse through the skin. These membranes are attached to the plastic containing a subsequent amount of drug material.

Subsequent preparation method

The subsequent is somewhat different, the drugs are inserted in the patch material like a matrix type and the mixed adhesive type. The mixture is manufactured in a different format known as the Hockenmeyer mixer. First, the adhesives are added and premixed at a higher speed for a prolonged period. Next, the other components such as gumminess control agents are added, and finally, mixing occurs. Further, drug additives are added up slowly. Final adjustment in pH or viscosity are made at the endpoint of preparation

Processing and packages

The processing depends on the type of bearer. Patches are filled with drug mixture and the reservoirs. The drug -adhesive material is covered with silicone treated polyester film. The silicon covered patches are easy to remove and exposes the adhesive layer. The nicotine patch 21 mg is oven-dried for eliminating the solvents and overlayered by a covering strip. The backing strip is again taken for processing the die-cutting and then packed as a finished product.

Nicotine content are easy to use, it helps to lower the longing nature of cigarettes. use the nicotine patches once and folded it down and dispose of it immediately. Use the patches for 10 minutes per day, by using the patches one can easily get rid of cigarettes.